Service hotline

+0086-139-2465-7372

BLOG

In China's rapid prototyping industry, suppliers generally offer competitive manufacturing capabilities across various processes, with achievable tolerances aligning with international standards for prototype and low-volume production. Below is an overview of typical dimensional tolerances, flatness, and geometric tolerances for key processes provided by most Chinese suppliers.

Dimensional Tolerance:

Metals (Aluminum, Steel, etc.): ±0.05 mm to ±0.1 mm for standard parts; high-precision machining can achieve ±0.02 mm or tighter.

Plastics (ABS, PC, Nylon, etc.): ±0.1 mm to ±0.2 mm, influenced by material stability and part size.

Flatness: Typically 0.05 mm to 0.1 mm per 100 mm span for standard machining; can be improved to 0.02 mm with precision milling or grinding.

Geometric Tolerances (Parallelism, Perpendicularity, Circularity):

Parallelism/Perpendicularity: 0.05 mm to 0.1 mm per 100 mm.

Circularity (Roundness): 0.02 mm to 0.05 mm for holes or shafts.

Positional Tolerance: ±0.05 mm to ±0.1 mm for features like holes or pins.

Dimensional Tolerance: ±0.2 mm to ±0.5 mm, depending on part orientation, layer height, and calibration.

Flatness: Limited by layer adhesion and warping; typically 0.3 mm to 0.5 mm per 100 mm.

Geometric Tolerances: Generally lower due to layer stacking; parallelism/perpendicularity around 0.3 mm to 0.5 mm.

Dimensional Tolerance: ±0.1 mm to ±0.2 mm, with high-resolution printers achieving ±0.05 mm.

Flatness: 0.1 mm to 0.2 mm per 100 mm, influenced by resin shrinkage and support structures.

Geometric Tolerances: Parallelism/perpendicularity within 0.1 mm to 0.2 mm.

Dimensional Tolerance: ±0.2 mm to ±0.3 mm for nylon-based materials; shrinkage is a key factor.

Flatness: 0.2 mm to 0.4 mm per 100 mm.

Geometric Tolerances: Similar to dimensional tolerances, with positional accuracy around ±0.2 mm.

Dimensional Tolerance: ±0.2 mm per 100 mm, or ±0.1 mm for smaller parts (<100 mm). Total tolerance can reach ±0.3 mm to ±0.5 mm for larger parts (>500 mm).

Flatness: 0.2 mm to 0.3 mm per 100 mm, influenced by mold quality and casting process.

Geometric Tolerances:

Parallelism/Perpendicularity: 0.2 mm to 0.3 mm per 100 mm.

Positional Tolerance: ±0.2 mm to ±0.4 mm.

Note: Tolerances depend heavily on the master pattern (often CNC-machined or 3D-printed) and silicone mold stability.

Bend Angle Tolerance: ±1° to ±2° for standard bends; precision tooling can achieve ±0.5°.

Linear Dimension Tolerance: ±0.2 mm to ±0.5 mm for cut/flange dimensions.

Flatness (After Bending): 0.2 mm to 0.5 mm per 100 mm, depending on material thickness and tooling accuracy.

Geometric Tolerances:

Parallelism between bends: 0.3 mm to 0.5 mm per 100 mm.

Hole-to-bend position: ±0.2 mm to ±0.4 mm.

Standard vs. Precision Tolerances: Most suppliers quote "standard" tolerances (as above). Tighter tolerances are often achievable but may incur higher costs and longer lead times.

Material Influence: Plastics and resins generally have wider tolerances than metals due to thermal expansion, shrinkage, or flexibility.

Part Size Consideration: Tolerances are often scaled with part dimensions (e.g., ±0.1 mm per 100 mm).

Design for Manufacturing (DFM): Suppliers usually provide DFM feedback to optimize tolerances based on the selected process.

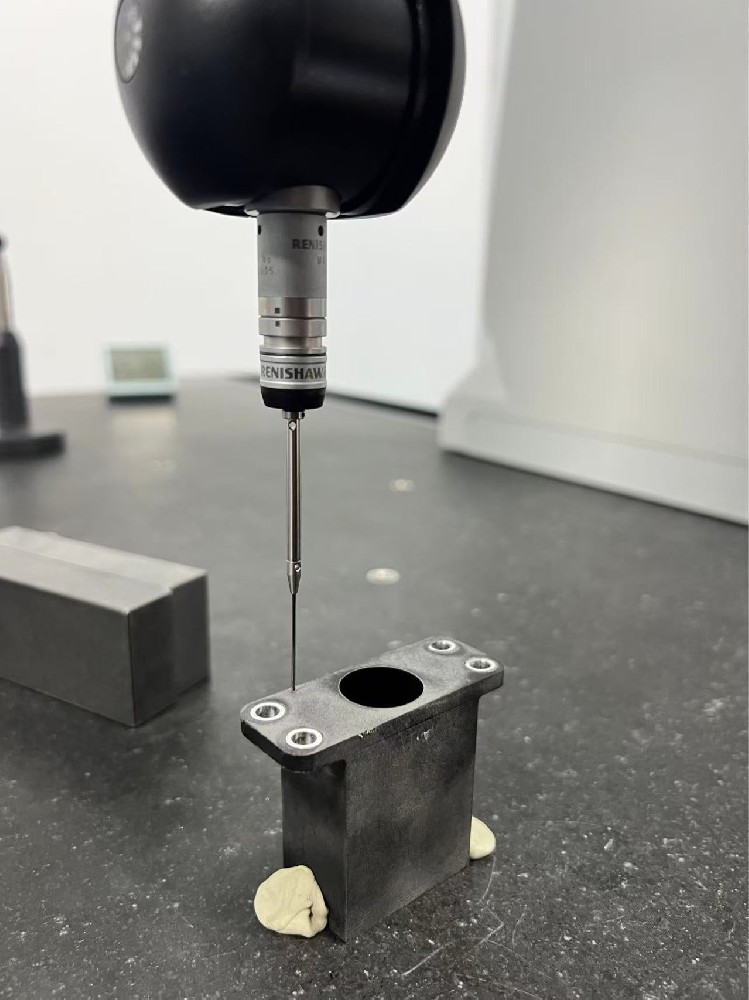

Quality Control: Leading suppliers use CMM (Coordinate Measuring Machine), laser scanners, and other inspection tools to verify critical tolerances.

| Process | Dimensional Tolerance | Flatness (per 100 mm) | Geometric Tolerance (Typical) |

|---|---|---|---|

| CNC Machining | ±0.05–0.1 mm | 0.05–0.1 mm | 0.05–0.1 mm |

| FDM 3D Printing | ±0.2–0.5 mm | 0.3–0.5 mm | 0.3–0.5 mm |

| SLA/DLP | ±0.1–0.2 mm | 0.1–0.2 mm | 0.1–0.2 mm |

| Vacuum Casting | ±0.2–0.3 mm | 0.2–0.3 mm | 0.2–0.3 mm |

| Sheet Metal Bending | ±0.2–0.5 mm | 0.2–0.5 mm | 0.3–0.5 mm |

For precise requirements, it is recommended to:

Specify critical tolerances on drawings and discuss them with the supplier early.

Request inspection reports for critical dimensions.

Consider prototyping before full production to validate tolerances.

ADD:Floor 4, Yongjianhong high-tech park, No.20, Songyu road, Songgang, Baoan district, Shenzhen,China 518105

TEL:+0086-139-2465-7372

E-MAIL:enquiry@pkprototype.com