Service hotline

+0086-139-2465-7372

BLOG

Shenzhen, often hailed as the "Hardware Silicon Valley" and the "Maker Capital of the World," is the premier global destination for prototyping and electronics manufacturing. Its unparalleled ecosystem—featuring the world's largest electronics market, dense supplier networks, and a culture of rapid iteration—makes it ideal for turning ideas into tangible prototypes. However, this very abundance can be overwhelming. Finding a truly qualified prototype supplier among thousands of options requires a strategic approach. Here is a practical guide to navigating this vibrant landscape.

1. Define Your Prototype Requirements with Precision

Before you search, crystallize your needs. A qualified supplier for a simple machined part differs vastly from one for a complex IoT device with embedded software. Specify:

Stage: Is it a proof-of-concept "looks-like" apperance model, a "works-like" functional prototype, or an engineering prototype for pre-production testing?

Materials & Processes: Do you need CNC machining service, 3D printing (SLA, SLS)service, sheet metal fabrication service, vacuum casting service, or PCB assembly (PCBA)service?

Quality & Tolerance: What are your critical dimensional tolerances, surface finish requirements, and functional standards?

Budget & Timeline: Have clear, realistic ranges for cost and urgency (e.g., 5-day vs. 30-day turnaround).

2. Leverage the Right Channels for Sourcing

Online Search Engine: Utilize search engine like Google, Baidu. Use specific keywords ("rapid prototype in Shenzhen," "low-volume production").

Specialized Prototyping Platforms: Consider services like FirstPCB (for PCBs), JLCPCB, or Seeed Studio's Fusion service, which are streamlined for low-volume, high-mix prototype work.

Industry Referrals & Networking: Tap into your professional network. Recommendations from other engineers or entrepreneurs are invaluable. Attend trade shows like the Shenzhen International Industrial Manufacturing Fair or maker events.

Huaqiangbei Exploration: For hands-on sourcing, visit the Huaqiangbei area. Buildings like SEG Plaza or Huaqiang Plaza are filled with component vendors and small assembly shops. This is best for simpler projects or sourcing components, but requires on-the-ground savvy.

3. Evaluate and Vet Potential Suppliers

Once you have a shortlist, move beyond website claims.

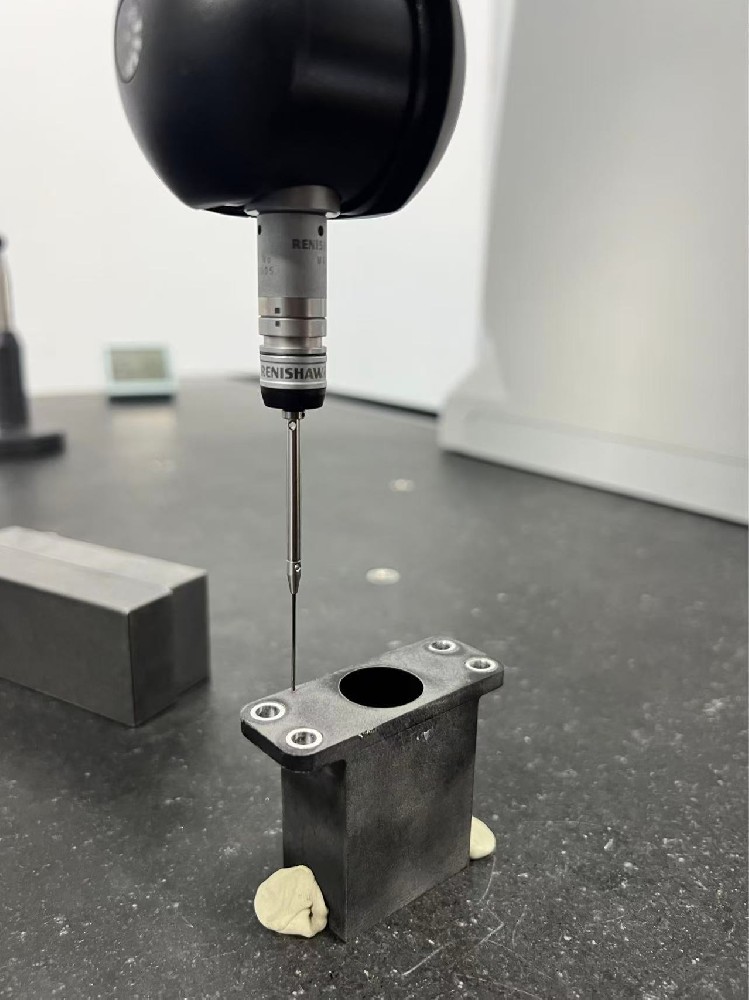

Technical Capability Audit: Request detailed case studies or portfolios of past projects similar to yours. Ask about their equipment list (brands and models of CNC machines, 3D printers, etc.) and in-house vs. outsourced processes.

Communication & Professionalism: Gauge their responsiveness and clarity. A qualified supplier will ask insightful questions about your design files (e.g., format, layer structure for PCBs), materials, and testing requirements. Poor English is not necessarily a deal-breaker, but a willingness to use translation tools and a proactive attitude are crucial.

Request for Quotation (RFQ): Send the same detailed package (CAD files, specifications, requirements) to multiple suppliers. Analyze the quotes not just on price, but on breakdowns (material cost, labor, setup), proposed processes, and lead time. Extremely low bids can be a red flag for compromised quality or hidden costs.

Factory Visit or Virtual Audit: If feasible, visit the facility. Look for organization, equipment maintenance, and skilled technicians. If not, request a video call for a virtual tour. Check for basic certifications (ISO 9001 is a good baseline for processes).

Sample or Small Test Order: Before committing to a critical prototype, order a simpler component or a previous sample from their portfolio. This is the most reliable way to assess actual quality, packaging, and shipping.

4. Focus on Partnership Over Transaction

A prototype supplier should be a collaborative partner in your development cycle.

Design for Manufacturability (DFM) Feedback: A qualified supplier will provide proactive DFM suggestions—pointing out design features that are difficult or expensive to prototype and suggesting modifications. This feedback is golden and can save you significant time and cost.

Transparency on Challenges: They should communicate problems early (e.g., material shortages, technical hurdles) rather than hiding them until a deadline is missed.

Scalability Consideration: Discuss if they can support the transition from prototyping to low-volume production, ensuring consistency.

5. Red Flags to Avoid

Uncritical Acceptance: A supplier that agrees to everything without questions likely lacks expertise or plans to cut corners.

Lack of Documentation: Unwillingness to provide process sheets, inspection reports, or clear contracts.

Vague Communication: Evasive answers to specific technical or logistical questions.

No Prototype/NDA Willingness: Refusal to sign a basic NDA to protect your IP before you share detailed designs.

Conclusion

Finding a qualified prototype supplier in Shenzhen is a process of diligent research, clear communication, and iterative testing. By defining your needs precisely, leveraging multiple sourcing channels, conducting thorough vetting, and prioritizing suppliers who act as technical partners, you can tap into Shenzhen's incredible manufacturing power. The goal is to build a relationship with a supplier who not only delivers a quality prototype but also becomes a reliable asset in your product development journey, helping you innovate faster and more effectively.

Prev:How to find a rapid prototyping supplier in China

Next:No More

ADD:Floor 4, Yongjianhong high-tech park, No.20, Songyu road, Songgang, Baoan district, Shenzhen,China 518105

TEL:+0086-139-2465-7372

E-MAIL:enquiry@pkprototype.com